HOOPS SDKs Help Visual Components Make Factory Planning and Simulation Easy for Its Customers

Visual Components & Tech Soft 3D

The Challenge

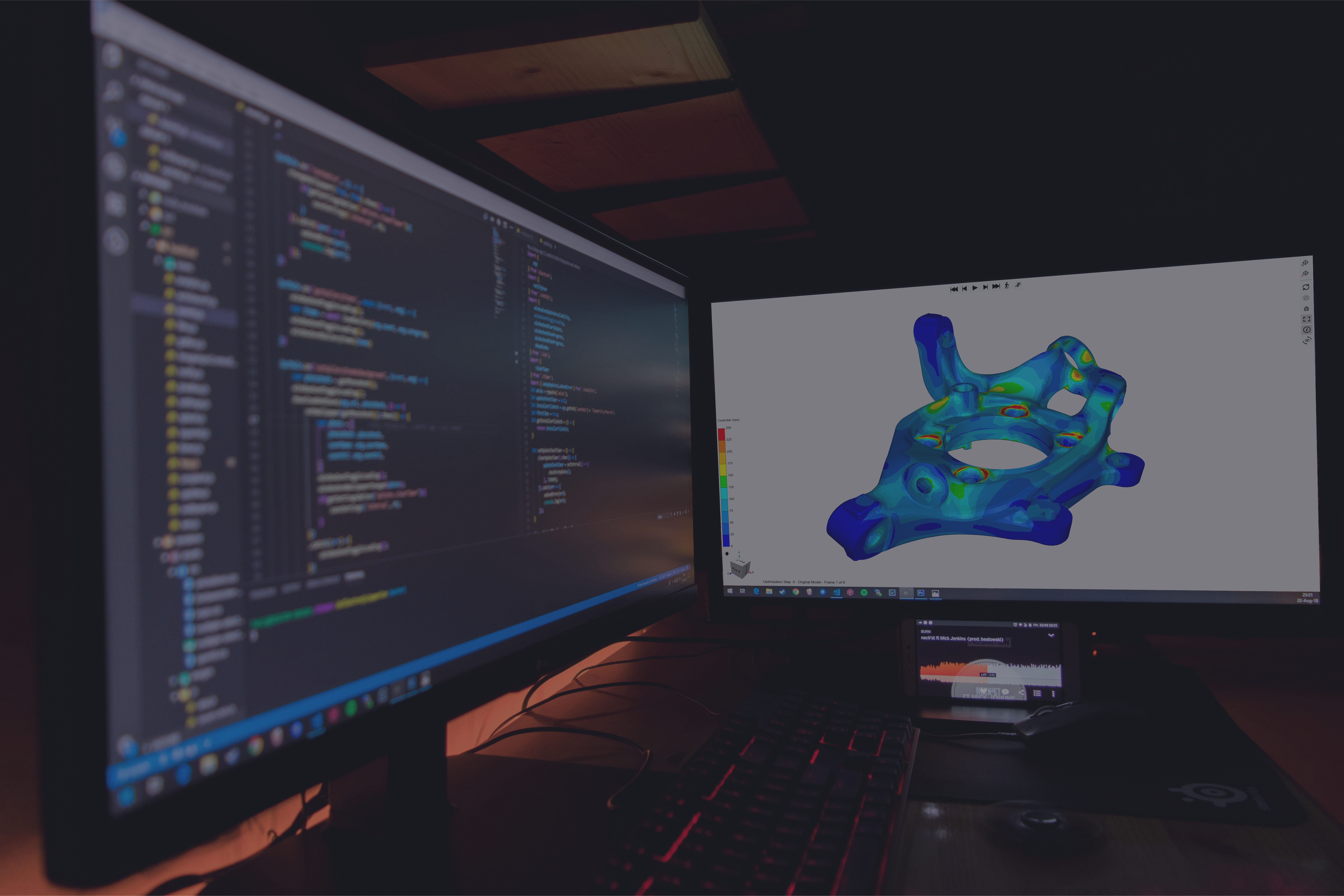

For more than 20 years, Visual Components has been one of the pioneers of the 3D manufacturing simulation industry. The company aims to make manufacturing design and simulation technology easy to use for manufacturing organizations of all sizes through its product, also called Visual Components.

“Visual Components’ focus is on simulation and robotics; those are the areas where we allocate most of our development resources. When development goes out of that scope – as with the challenge of providing robust 3D data access – we look for reliable SDKs like HOOPS Exchange that complement our existing functionalities.”

Camilo Cifuentes, Senior Software Developer, Visual Components

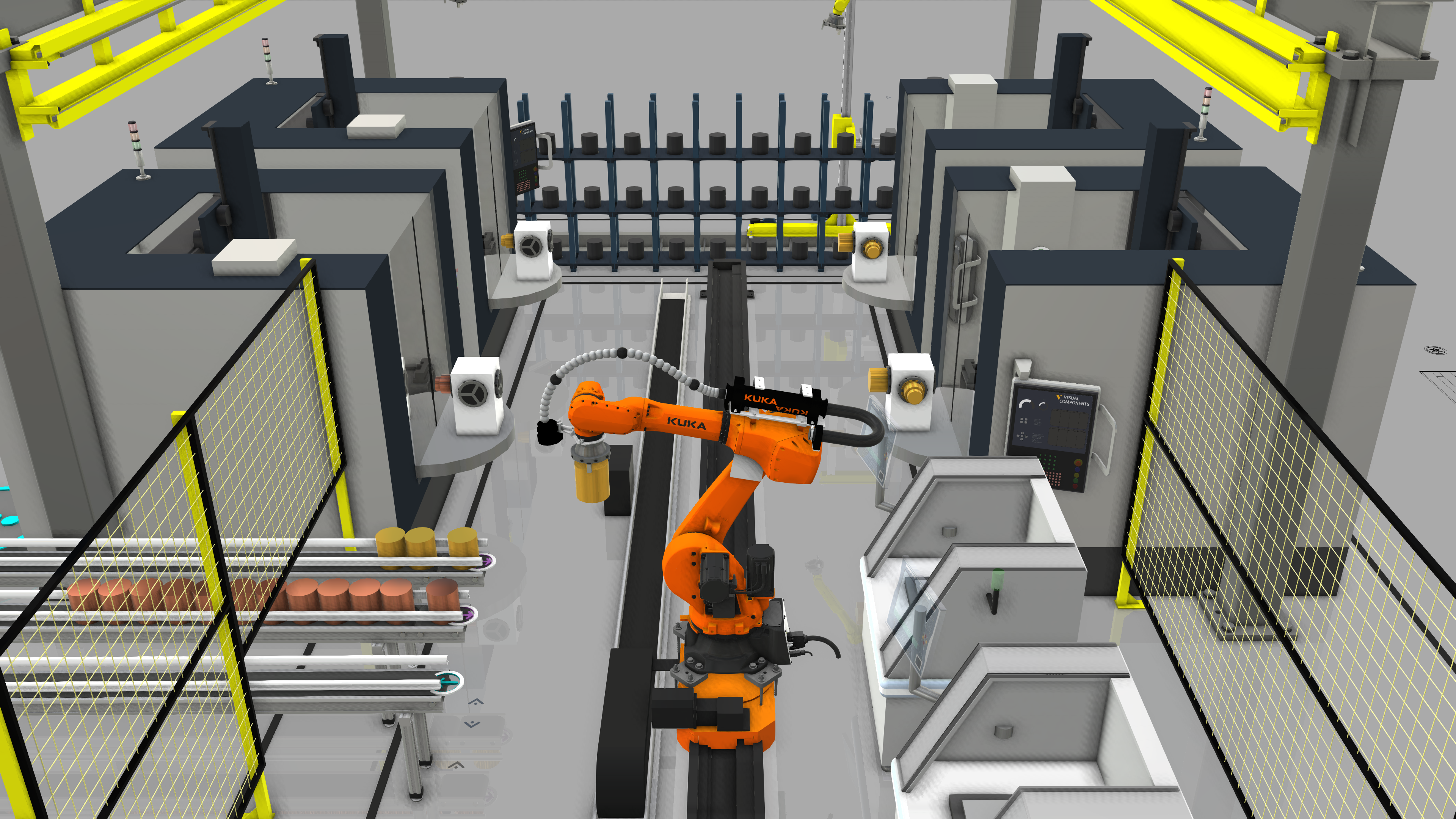

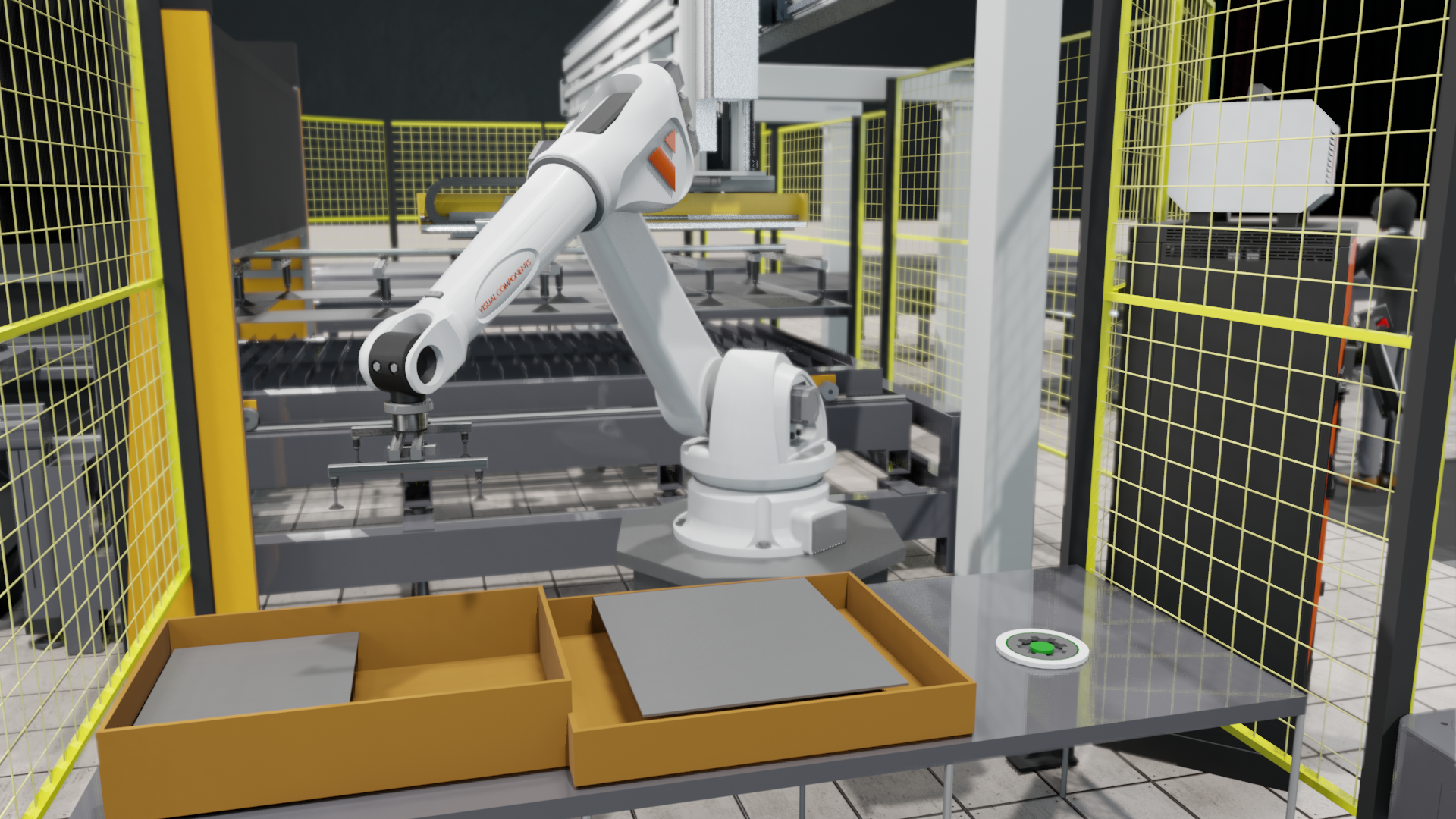

“We offer a simulation solution for planning all kinds of manufacturing environments, from automotive to the food and beverage industry. The simulation allows testing the plans and optimizing the production processes without committing investment in physical systems,” said Umair Ejaz, Product Marketing Manager at Visual Components. “It gives customers a virtual environment where they can design their layouts in advance, program their robots, and run simulation studies to make sure there aren’t any bottlenecks and all the elements of the shop floor are working efficiently.”

To help populate this virtual factory environment, customers can use the product’s eCatalog feature, which provides access to thousands of ready-made models of robots and other industrial automation machinery from leading brands, or they can bring in their own CAD data and add simulation behavior to the CAD models if desired. To accommodate this latter scenario, Visual Components knew that it needed to provide support for a wide variety of CAD files and formats.

“Looking at our customer base, we understand that there aren’t just one or two primary CAD tools out there – there are scores of them,” said Ejaz. “The type of CAD package is going to be different from company to company – it might even be different from project to project within an organization. Our product has to support that diversity of CAD formats and also its continuous version updates.”

Creating Easy Ways to Bring Data In and Push It Out

To ensure it could provide access to wide variety of CAD formats, Visual Components turned to HOOPS Exchange. An SDK that enables the import of 30+ popular CAD formats, HOOPS Exchange is the leading CAD import and export library and is able to bring in complex data with no loss of accuracy or precision.

Explaining the company’s decision to utilize HOOPS Exchange, Camilo Cifuentes, Senior Software Developer at Visual Components, said: “Visual Components’ focus is on simulation and robotics; those are the areas where we allocate most of our development resources. When development goes out of that scope – as with the challenge of providing robust 3D data access – we look for reliable SDKs like HOOPS Exchange that complement our existing functionalities.”

The company is also making use of HOOPS Publish, a native SDK for generating interactive 3D PDF documents and exporting to HTML and other formats for easy downstream consumption of 3D models and engineering data. Together, the two HOOPS SDKs build powerful functionality into Visual Components.

“HOOPS Exchange enables us to import 3D models into our own 3D planning environment, bringing in not just the geometries, but also material, texture, PMI, and other information,” said Cifuentes. “When it comes time to export this information, we use HOOPS Publish to generate 3D interactive PDFs.”

The richness of the export functionality is particularly useful for making simulations of factory performance more easily understandable and less abstract for downstream users.

“While running a factory simulation in Visual Components, customers have the option of hitting ‘record’ to capture several minutes of their factory in action,” said Cifuentes. “HOOPS Publish [now part of HOOPS Exchange] makes it simple for our customers to share that 3D animated simulation and the related data in a format that pretty much anyone with a computer can open and access. The recipients don’t need to buy or run any special software to experience the simulation in a very in-depth fashion.”

From a technical perspective, incorporating the SDKs into Visual Components and working with Tech Soft 3D has been a smooth process for the company, marked by a high level of responsiveness. “We’ve been using HOOPS Exchange for nearly seven years now, and the support from Tech Soft 3D has been amazing,” said Cifuentes. “When you’re first getting started, they provide very useful sample projects and data that help you understand how to work with the SDK to get the results you need. When we had questions, Tech Soft 3D were very quick to provide answers.”

Ejaz, focusing on the foundational role of the SDKs, summed up the relationship by saying: “The ability to bring different types of 3D data into simulation software is indispensable. Quite simply, Tech Soft 3D's partnership has been essential to us.”

Industry:

Robotics, Factory Planning and Simulation

Challenge:

Manufacturing customers need ability to simulate factory performance to maximize output and resource utilization - Accurate simulation requires bringing in CAD models of different industrial automation assets and machinery in a variety of CAD formats - Downstream users require easy way to consume simulation results

Solutions:

Tech Soft 3D provides SDKs that power world-class engineering applications and provide easy ways to import and export 3D engineering data

Results:

Allow in-house development resources to focus on core competency of simulation and robotics - Provide support for customers’ heterogeneous CAD environments with support for 30+ CAD formats - Share rich engineering data like simulation animations with downstream users in the form of easily accessible interactive 3D PDFs